Jigsaw puzzles, those captivating challenges that test our patience and problem-solving skills, have been a source of entertainment for generations. But have you ever wondered how these intricate interlocking pieces come to life? The journey from concept to completed puzzle involves a fascinating blend of artistry, engineering, and precision manufacturing. Let’s delve behind the scenes and explore the process of how jigsaw puzzles are made.

Part 1: From Inspiration to Image – The Design Process

1. Selecting a Compelling Image:

The magic of a jigsaw puzzle starts with a captivating image! Manufacturers have a keen eye for picking the perfect picture. They seek out vibrant scenes bursting with color and intricate details, like breathtaking landscapes, iconic works of art, or beloved characters that bring back childhood memories. But the possibilities don’t stop there! Some innovative companies let you personalize the puzzle experience by transforming your own cherished photos into custom puzzles. Imagine the joy of piecing together a family vacation picture or a heartwarming moment with friends. These personalized puzzles add a sentimental touch to the classic challenge, creating a unique and treasured keepsake.

2. Enhancing the Challenge:

Once the image is chosen, puzzle designers go to work on creating the interlocked pieces. This involves using specialized software to digitally manipulate the image and develop a cutting pattern. The software considers factors like difficulty level, piece size, and the desired level of challenge for the puzzle solver. More complex puzzles may incorporate a variety of piece shapes, including unique or irregular shapes, to increase the difficulty.

Part 2: Crafting the Tools – Die Cutting and Punching

1. The Power of Precision:

With the cutting pattern finalized, it’s time to create the tools responsible for shaping the puzzle pieces. These tools are typically made from high-quality steel and are known as “puzzle dies.” Die cutters use computer-aided design (CAD) software to create intricate patterns on the steel, replicating the shapes of the puzzle pieces. Extreme precision is crucial during this stage to ensure each piece fits together seamlessly.

2. Punching Out the Pieces:

Once the steel dies are complete, they are used in powerful punching machines. These machines exert tremendous pressure, forcing the dies through sheets of material, typically cardboard or compressed paperboard, to stamp out the individual puzzle pieces. The punching process is incredibly efficient, allowing for the rapid production of large quantities of puzzle pieces.

Part 3: Building the Puzzle – Material Selection and Finishing Touches

1. The Foundation of the Puzzle:

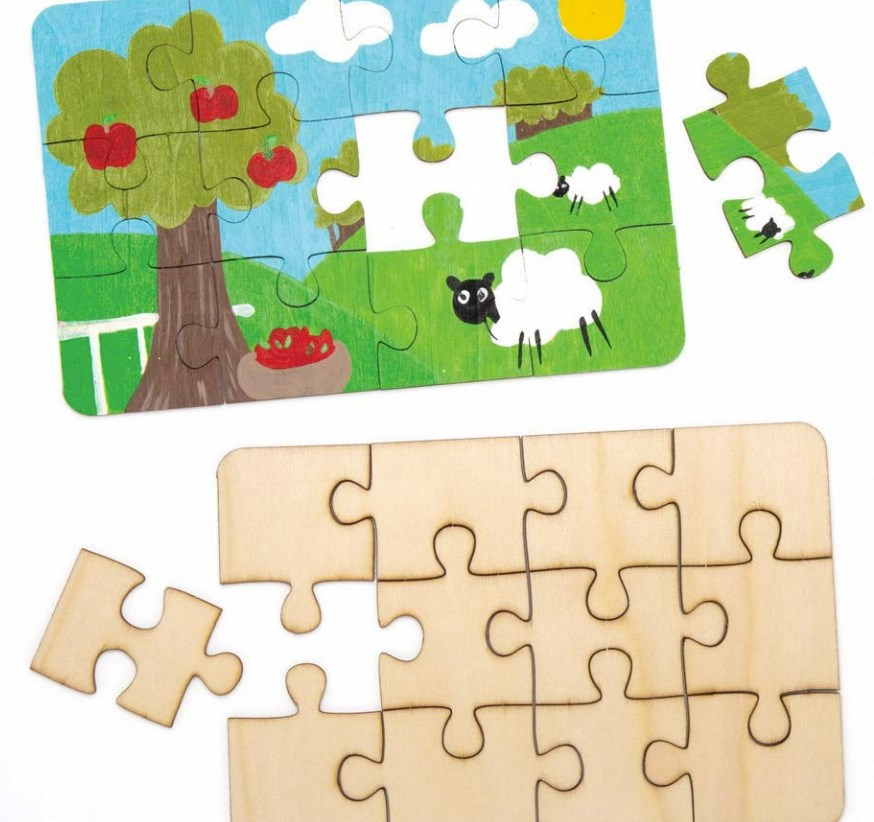

The foundation of a jigsaw puzzle plays a big role in its puzzling experience! The most common choice is cardboard, a budget-friendly and printable material that keeps puzzles accessible to everyone. However, for those seeking a more luxurious experience, some manufacturers elevate the game by using premium materials. Imagine a puzzle crafted from smooth wood, offering a satisfying tactile experience and a sturdiness that allows you to move sections around without fear of damage. Or picture a puzzle made from high-quality acrylic, creating a translucent and almost jewel-like quality to the finished product. These premium materials elevate the puzzle from a game to a heirloom, something to be cherished and enjoyed for generations.

2. Adding Color and Shine:

Once the puzzle pieces are punched from their cardboard or sturdier base, they take a trip to the printing press. Here’s where the magic truly comes alive! Modern printing techniques are like tiny artists, meticulously applying the chosen image onto each puzzle piece. They use vibrant inks that bring landscapes to life, capture the subtle details of a masterpiece, or make cartoon characters pop with color. The result? A visually stunning puzzle that beckons you to start piecing together the scene. But some manufacturers take it a step further. They might add a matte finish, creating a smooth, almost velvety texture that feels luxurious in your hands. Or, they might opt for a glossy finish, making the colors appear even richer and adding a touch of shine to the completed puzzle.

Part 4: Quality Control and Packaging – Ensuring a Smooth Experience

1. The Importance of Precision:

Once the pieces are printed and cut, they undergo rigorous quality control checks. This process ensures that the pieces are free of defects like missing sections, incorrect shapes, or printing errors. Quality control inspectors remove any puzzles that fail to meet the standards from the production line.

2. Preparing for Play:

The completed puzzle pieces are then carefully packaged. The box typically includes the finished image as a reference guide, along with information about the artist or the puzzle’s theme. Some manufacturers may also include resealable bags to help puzzle solvers sort and organize the pieces during assembly.

Part 5: The Future of Puzzles – Innovation and Sustainability

1. Beyond Traditional Puzzles:

The world of jigsaw puzzles is bursting with innovation! Gone are the days of just one image and a flat challenge. Tech-savvy manufacturers are pushing the boundaries, dreaming up new ways to tantalize puzzle enthusiasts. Imagine tackling a puzzle with not one, but two captivating images! Double-sided puzzles offer a mind-bending challenge, forcing you to strategically flip pieces and consider the artwork from entirely different perspectives. But the fun doesn’t stop there. 3D puzzles are taking the experience to a whole new level. These puzzles allow you to build miniature sculptures or even life-like replicas of famous landmarks, piece by intricate piece. The satisfaction of constructing a 3D model of the Eiffel Tower or the Colosseum from tiny puzzle pieces adds a whole new layer of accomplishment to the classic challenge. So, next time you’re looking for a puzzle, keep an eye out for these innovative designs.

2. Sustainable Practices:

As environmental concerns grow, puzzle manufacturers are increasingly looking for ways to make their products more sustainable. This may involve using recycled materials for the puzzle base or implementing eco-friendly printing processes. Additionally, some companies are exploring the use of biodegradable or compostable materials for puzzle packaging, minimizing their environmental footprint.

In conclusion, meticulous planning, innovative technology, and a commitment to quality fuel the journey of a jigsaw puzzle, from a captivating image to a completed challenge. As you embark on your next puzzle adventure, take a moment to appreciate the intricate craftsmanship behind each piece. The next time you find yourself engrossed in sorting and fitting together those interlocking pieces, remember the artistry, engineering, and precision that went into creating this timeless form of entertainment. Jigsaw puzzles offer a delightful blend of challenge, relaxation, and a sense of accomplishment. So, the next time you’re looking for a fun and stimulating activity, grab a jigsaw puzzle, and embark on a journey of discovery, one piece at a time.