Introduction

In the realm of hobbies, few things bring as much joy and excitement as operating remote-controlled vehicles. Among these, the 3D printed RC boat stands out as a unique innovation that combines creativity with functionality. As hobbyists strive for customization and personalization in their creations, 3D printing technology has opened a new realm of possibilities. This article delves into the features, advantages, and fun aspects of owning a 3D printed RC boat. Whether you’re a novice enthusiast or a seasoned pro, you will find that this cutting-edge hobby offers something for everyone.

What is a 3D Printed RC Boat?

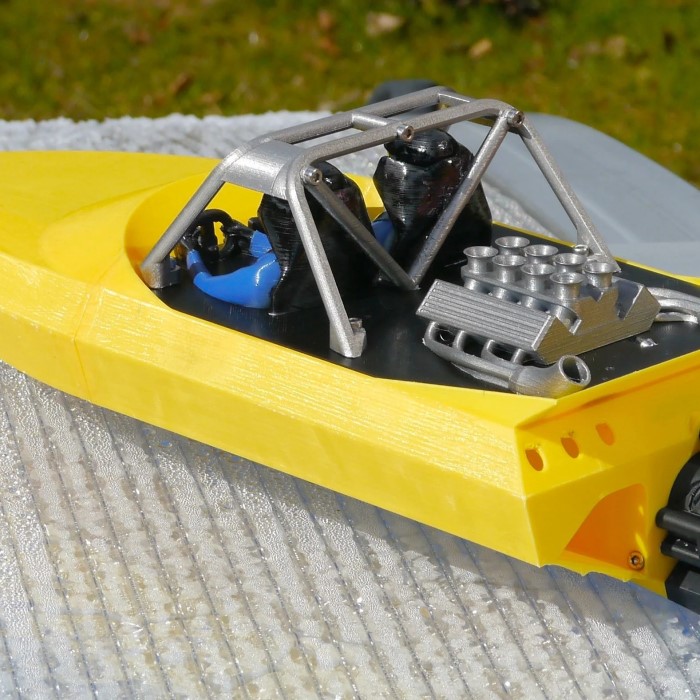

A 3D printed RC boat is a remote-controlled watercraft created using 3D printing technology. This approach allows for the design and fabrication of unique boat models that standard production methods could not achieve. Unlike traditional RC boats, which often come in set designs, a 3D printed RC boat can be completely customized—from the hull shape to the details of the deck.

Key Components of a 3D Printed RC Boat

- 3D Printing Technology: Utilizing additive manufacturing techniques, 3D printed RC boats are created layer by layer, enabling intricate detailing and complex geometries that traditionally manufactured boats cannot achieve.

- Materials: Many enthusiasts utilize plastics like PLA, ABS, or PETG when printing their boats. Each material offers different properties, such as durability, buoyancy, and weight.

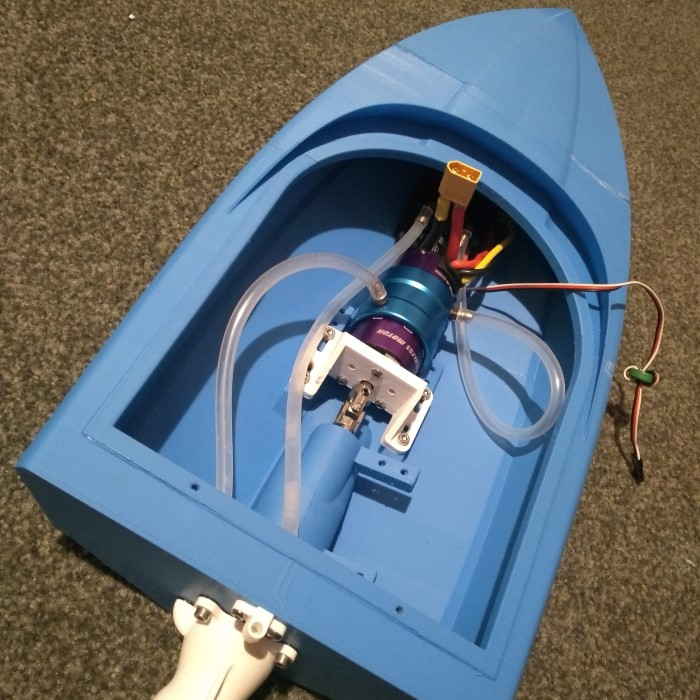

- Electronics: A typical setup includes a motor, receiver, battery, and servos. These components facilitate the movement of the boat, enabling you to control speed and direction seamlessly.

By embracing this innovative technology, hobbyists not only customize their models but also enhance their understanding of engineering and design principles.

The Benefits of Owning a 3D Printed RC Boat

Investing in a 3D printed RC boat can provide multiple benefits. Understanding these advantages can help you appreciate why this innovative hobby has gained popularity among enthusiasts.

1. Customization at Your Fingertips

One of the most significant advantages of a 3D printed RC boat is the customization it allows. You can create designs tailored to your exact specifications. For instance, whether you want a sleek racing boat or a sturdy fishing vessel, the possibilities are endless. You can also personalize your boat with specific colors, logos, and features that reflect your personality or interests.

- Endless Design Options: With 3D design software, the only limit is your imagination. You can create everything from classic yacht designs to futuristic speedboats.

- Personal Touches: Decorate your boat with stickers or themes that represent your favorite colors or characters, making it truly yours.

2. Cost-Effectiveness

While the initial cost of 3D printing equipment might seem high, the long-term savings can be significant. Once you own a 3D printer, the ongoing costs mainly include materials and some electronic components. Additionally, you can produce multiple boats or spare parts without incurring high expenses typically associated with buying ready-made models.

- Affordable Materials: Filament for your 3D printer ranges in price, with options that allow you to create multiple boats without breaking the bank.

- Repairs and Modifications: Unlike traditional boats, which may require purchasing new parts, a 3D printed boat can easily be repaired or modified by simply printing new components.

3. Educational Opportunities

Building a 3D printed RC boat opens the door to valuable educational experiences. You can learn about various concepts, including hydrodynamics, materials science, electronics, and design principles. For younger enthusiasts, these elements can foster an interest in STEM (Science, Technology, Engineering, and Mathematics) fields, as the process encourages critical thinking and problem-solving.

- Interactive Learning: While assembling the components or troubleshooting issues, you gain hands-on experience that improves problem-solving skills.

- STEM Inspiration: The fun of operating your boat can lead to deeper interest in engineering, physics, and technology.

4. Community Engagement

The 3D printing community is vast and supportive. When you embark on the journey of creating a 3D printed RC boat, you become part of a network of like-minded enthusiasts. Online forums, social media groups, and local clubs provide ample opportunities for sharing designs, tips, and experiences. Engaging with this community can enhance your skills and ignite new ideas for your projects.

- Sharing Knowledge: Interacting with fellow hobbyists can lead to helpful advice, especially for beginners facing challenges in their builds.

- Collaborative Projects: Team up with others for events or challenges, fostering camaraderie and shared learning experiences.

Fun Activities with Your Printed RC Boat

Having a 3D printed RC boat isn’t just about building; it’s also about enjoying various activities with it. Here are some fun ideas to maximize your enjoyment:

1. Racing Events

Join local racing clubs or organize your own contests with friends and family. Racing against others can be thrilling and encourages friendly competition.

- Set Race Rules: Establish clear rules for the races to ensure fairness, such as time trials or obstacle courses.

- Improve Performance: Use the races to test and tweak your boat for better speed, handling, and stability.

2. Water Exploration

Use your 3D printed RC boat to explore lakes, ponds, or rivers. Watching your creation sail across the water can be immensely satisfying.

- Natural Observation: This activity provides an opportunity to observe wildlife and enjoy nature while enjoying your boat.

- Photography Sessions: Capture those memorable moments with photographs or videos, showcasing both your boat and the scenic beauty around you.

3. Custom Challenges

Create unique challenges that test the abilities of your 3D printed RC boat. From navigating mazes to completing tasks, these challenges promote creativity and problem-solving.

- Obstacle Courses: Design a course with hurdles or color markers that your boat has to navigate around.

- Timed Challenges: Set time limits on certain tasks to add excitement and encourage competition.

FAQ: Common Questions

How Much Does a 3D Printed Boat Cost?

The cost of a 3D printed RC boat can vary greatly based on several factors. The price of materials, the complexity of the design, and the quality of electronics all influence the final expense. On average, the cost of filament for a single boat may range from 20to50. However, when you factor in the electronics and any additional components, such as motors and batteries, the total cost can be between 100and300. Overall, it frequently proves to be a more economical choice than purchasing a commercial model.

Is It Possible to 3D Print a Boat?

Yes, it is entirely possible to 3D print a boat. The key lies in the choice of materials and designs. Different filament types have varying properties; some can be buoyant and water-resistant. While smaller, lightweight boats are easier to print, larger models require careful consideration of weight and structural integrity. Many hobbyists have successfully printed both small RC boats and full-sized boats using advanced 3D printing techniques and materials.

Is 3D Printing Good for RC Planes?

Absolutely! 3D printing technology is equally effective for creating remote-controlled planes. The same principles that apply to boats can be employed in designing lightweight airframes and intricate components for RC aircraft. Those who engage in this hobby often find that 3D printing allows for more experimentation, leading to unique designs, improved performance, and greater customization compared to traditional methods.

Can a 3D Printed Boat Float?

Yes, a well-designed 3D printed boat can float if constructed with the appropriate materials and considerations. Ensuring that the design incorporates sufficient buoyancy, choosing lightweight materials, and carefully arranging the internal components contribute to the boat’s floatation. While there may be challenges, many hobbyists creatively overcome these obstacles to produce functional and impressive 3D printed boats.

Building Your 3D Printed RC Boat

If you’re ready to dive into this exciting hobby, here are some key steps to consider for building your very own 3D printed RC boat:

1. Design Your Model

Start by sketching your design or using a CAD (Computer-Aided Design) program. There are plenty of pre-made designs available online, or you can create something uniquely yours. Consider the purpose of your boat—speed, stability, or versatility—and design accordingly.

- Focus on Purpose: Determine whether you want a racing model or something more rugged for exploration to guide your design choices.

- Utilize Templates: Many online resources offer templates to simplify the initial design process.

2. Choose the Right Material

Selecting the right filament is crucial. PLA is ideal for beginners due to its ease of use, while ABS is suitable for users needing durability for outdoor use. Investigate specialty filaments that may offer water resistance or flexibility, depending on your design.

- PLA vs. ABS: Understand the differences between materials, such as printability and resilience against environmental factors.

- Explore New Materials: Investigate advanced filaments like nylon or flexible materials for specific needs.

3. Print the Components

Once your design is complete and your material chosen, it’s time to print! Ensure that your 3D printer settings are optimized for quality. Pay attention to details like layer height and infill percentage, as they can influence the structural integrity of your boat.

- Slow and Steady: Start with slower print speeds for better quality. Ensure the nozzle temperature is set according to the filament specifications.

- Print Orientation: Consider the best orientation for printing different parts to avoid unnecessary supports and ensure strength.

4. Assemble Your Boat

After printing, assemble all components while ensuring that you securely attach the electronic parts. While doing this, test each system and connection to ensure functionality.

- Careful Assembly: Follow instructions carefully to prevent damage. Use appropriate adhesives or screws as needed.

- Check Electronics: Before sealing, verify that all motors and servos are functioning correctly.

5. Conduct Tests

Before taking your 3D printed RC boat out on the water, conduct dry tests to verify the functionality of motors and controls. Once you’re confident in the mechanics, take it for a test run on calm water to observe how it performs.

- Initial Dry Tests: Ensure all components respond correctly in a controlled environment, allowing you to make adjustments if necessary.

- Test on Calm Water: When testing on water, pick a day with minimal wind to better assess the boat’s handling.

Conclusion

In summary, a 3D printed RC boat represents a fascinating blend of technology, creativity, and education. Embracing this hobby allows enthusiasts to customize their watercraft in ways that traditional methods cannot achieve. With the insights provided in this article, you can unlock the immense fun and satisfaction of creating and operating your own 3D printed RC boat.

As you engage in this innovative realm, appreciate the learning opportunities it provides while connecting with fellow hobbyists. Whether you choose to focus on design, engineering, or simply having fun on the water, a 3D printed RC boat presents an engaging and rewarding experience. Now, set sail on your creative journey and explore the endless possibilities that await you in the world of 3D printed RC boats!